VIEW LATEST UPDATES ON LINKEDIN

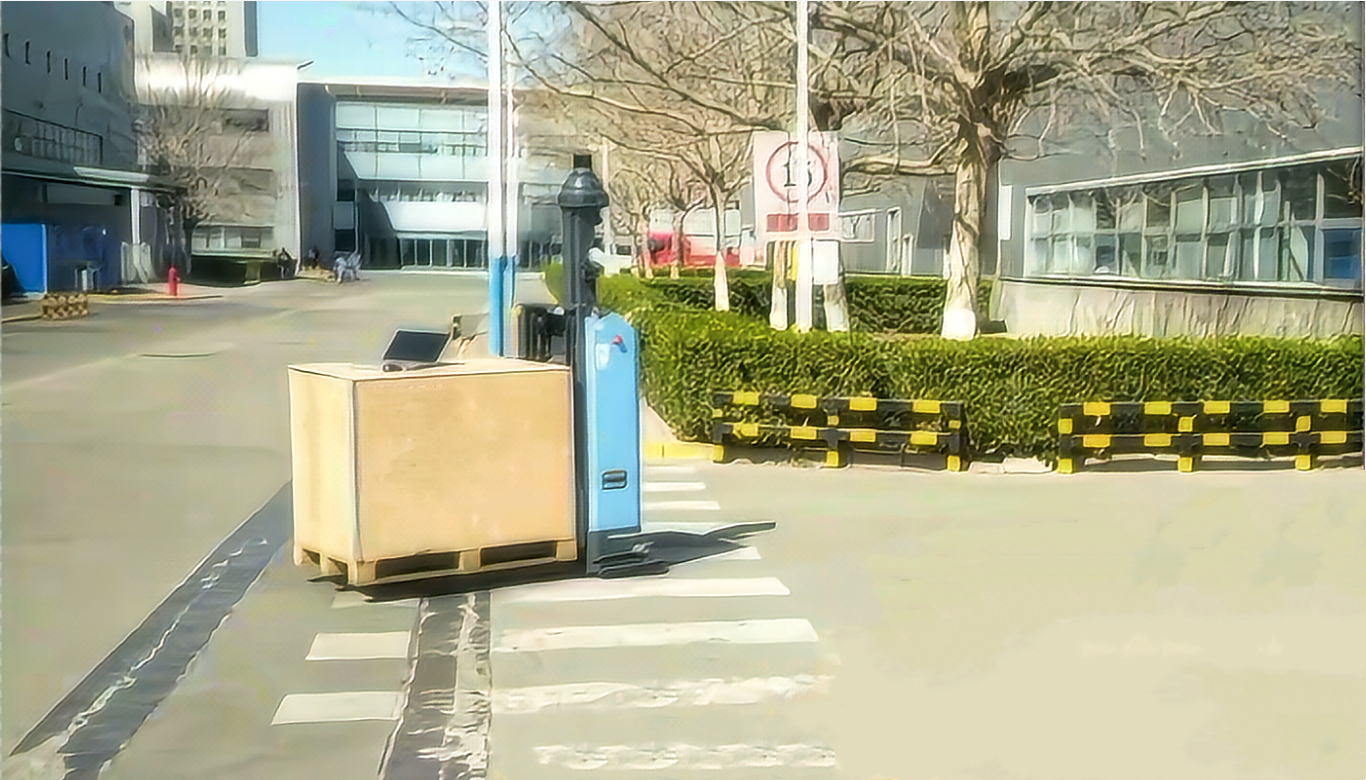

27 ROBOTS! GEM COLLABORATES WITH SEER ROBOTICS TO CREATE A NEW PARADIGM FOR INTELLIGENT UPGRADING IN THE NEW ENERGY SECTOR

As a core enterprise in the new energy materials sector, GEM (Wuxi) focuses on the R&D of new energy lithium-ion batteries and the full lifecycle management of power batteries. It has established a finely-tuned, non-destructive, intelligent disassembly line with an annual processing capacity of 50,000 sets of used vehicle power batteries, striving to build a world-class circular factory for renewable resources.

MORE

SEER ROBOTICS ASSISTS SCHNEIDER ELECTRIC USA IN ACCELERATING WAREHOUSE TRANSFER AUTOMATION

In recent years, several core Schneider Electric factories in China have successively adopted SEER Robotics' intelligent logistics solutions, continuously optimizing production processes and achieving exponential efficiency gains. Thanks to these successful cases, Schneider Electric USA has also chosen to collaborate with SEER Robotics in its journey toward intelligent logistics construction.

MORE

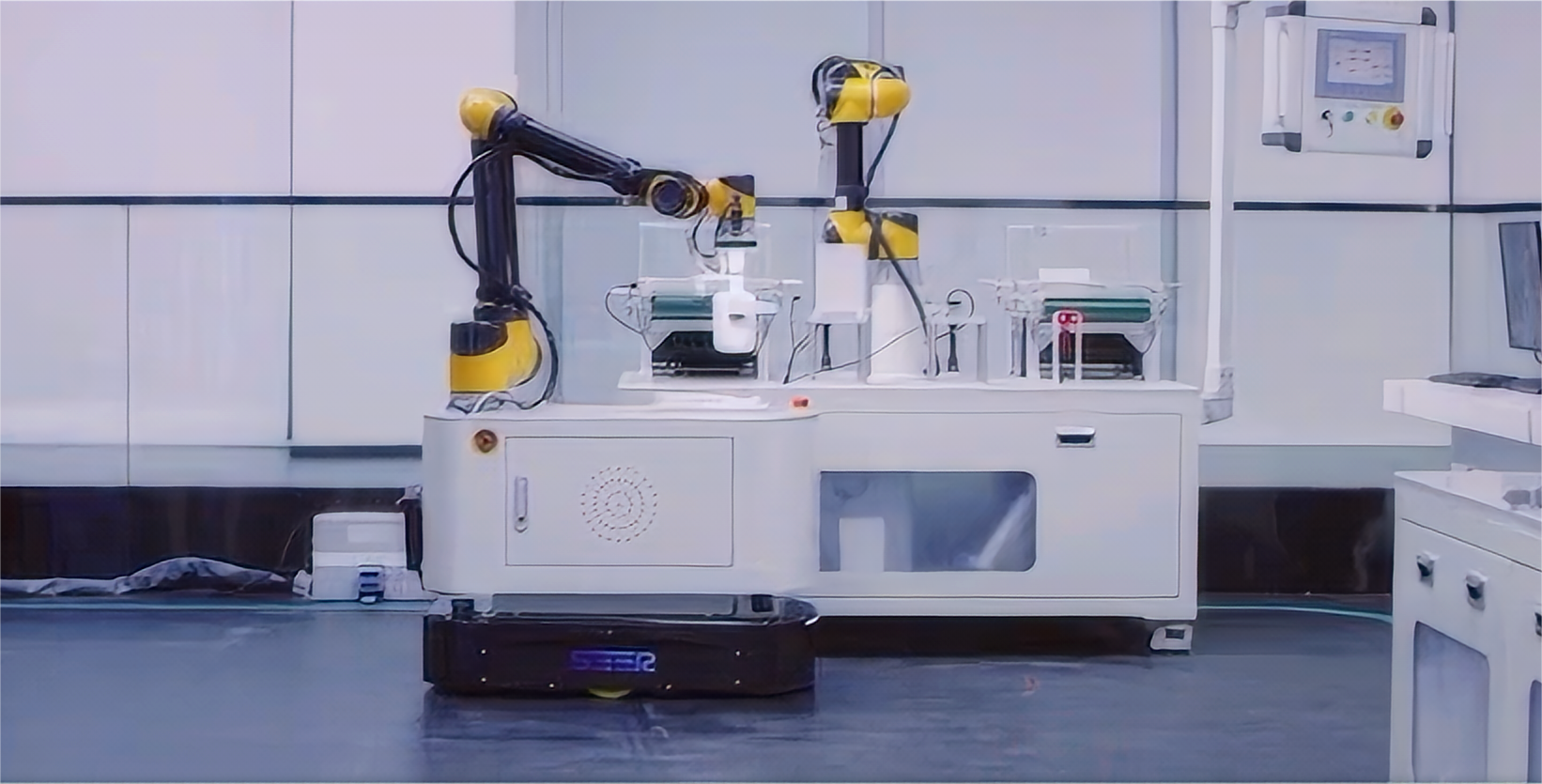

INTELLIGENT LAB ASSISTANT: XIMAGING'S INNOVATIVE APPLICATION BASED ON SEER ROBOTICS AMB CHASSIS

In the field of scientific experiments, the workflow of the laboratory is being revolutionized towards diversification and intelligence with the growth of data processing and the increase of experimental complexity. At the same time, the improvement of technology makes the demand for robots in laboratories become more and more urgent and specific.

MORE

BREAKING THE 1CM GAP LIMIT! SEER ROBOTICS BOOSTS MULTI-PROCESS AUTOMATION AT ELECTROLUX'S SWEDEN FACTORY

To achieve sustainable development goals, Electrolux has proposed higher production requirements and hopes to introduce intelligent robots to integrate with the factory's existing intelligent equipment and operational processes, achieving automation and unmanned operation in three major production processes.SEER Robotics, in conjunction with European integrators, has created a customized intelligent logistics solution for them. Through the Unified Resource Dispatching System (RDS), six intelligent forklifts work orderly in three transportation lines, covering multiple processes from semi-finished to finished product transfer.

MORE

PHILIPS X SEER ROBOTICS, CE-CERTIFIED STACKING FORKLIFTS ACCELERATE AUTOMATED HANDLING.

Philips plans to introduce intelligent forklifts into the production area, using them to transport empty racks from the warehouse to the production buffer zone. Previously, this process required manual handling, with high racks and certain weight, posing high physical demands and safety risks for employees.

MORE

TRIPLE EFFICIENCY BOOST! WINFAT ELECTRONICS PARTNERS WITH SEER ROBOTICS FOR SMART UPGRADE

WINFAT ELECTRONICS is a high-tech manufacturing enterprise integrating design, R&D, production, sales, and service. It specializes in intelligent educational electronics, electric electronic toys for infants, and children, with its own independent garden-style industrial park.

MORE

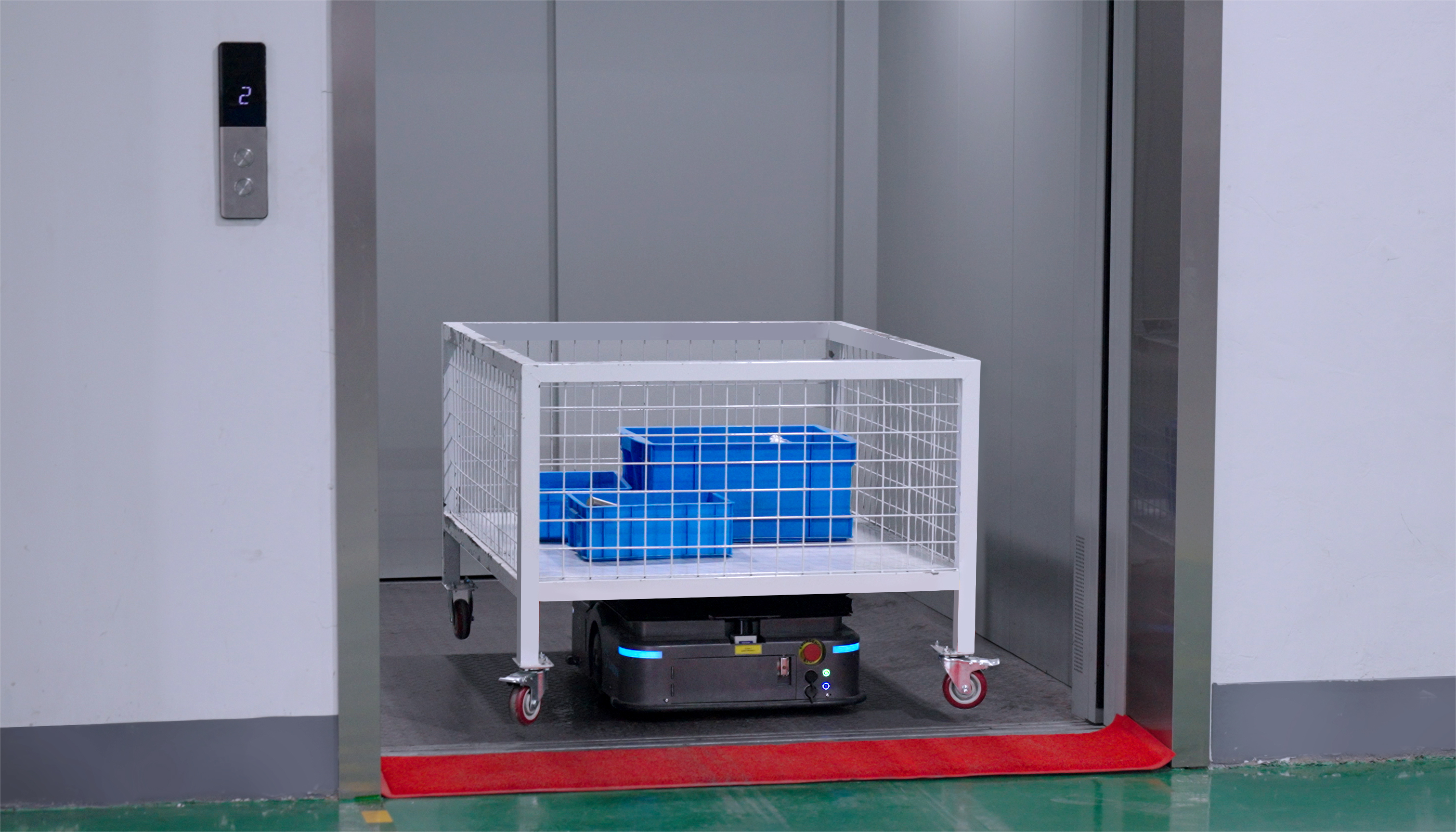

CHUZHOU HKC WORKS WITH SEER ROBOTICS TO BUILD IN-PLANT INTELLIGENT LOGISTICS TO HELP THE WORKSHOP TRANSFER EFFICIENTLY!

Recently, the Chuzhou HKC mobile robot project, the leader of panel manufacturing service of SEER Robotics, was officially put into use in the workshop, helping it to build an intelligent logistics workshop, maximize the efficiency of cargo transfer, and provide strong support for the whole process business of the production line.

MORE

LIGHTHOUSE FACTORY UPGRADE AGAIN! SEER ROBOTICS HELPS INTELLIGENT FLOW OF 3C ELECTRONIC MANUFACTURING PRODUCTION LINE

One fortune 500 company in France. Pro-face is one of the 90 "lighthouse factories" in the world. Due to the large production workshop area and scattered production vehicles, and because the cooperation of various production lines and handling is carried out in the form of manpower + magnetic stripe carts, coupled with the system of working on two sides and difficult-to-handle materials, many companies face high labor costs and low handling efficiency. As the industry-leading lighthouse factory, it is looking for a smarter and more flexible circulation form of the production line.

MORE

SEER ROBOTICS + GATHERS INTELLIGENT MANUFACTURING TO CREATE A DIGITAL EXHIBITION HALL OF SIEMENS

SEER Robotics and Jicui Intelligent Manufacturing have joined forces to create the Siemens Industrial Innovation Center exhibition hall, which is used to display siemens intelligent audio, driving recorders and other products.

MORE

SFL-CDD14 FOR VNA! DEDICATED TO IMPROVING PRODUCTIVITY IN INDUSTRIAL EQUIPMENT MANUFACTURING

The customer coming on the scene is mainly engaged in the production, manufacturing, research, development and application of high-voltage variable-frequency drives, with a plant area of over 5,500 square meters and a footprint of about 15,000 square meters. Owning strong technical force, the customer is committed to providing high-quality high voltage variable frequency drives, and delivering varied applications as well as comprehensive & complete services.

MORE

SEER ROBOTICS LOGISTICS SOLUTION FOR 3C MANUFACTURING WORKSHOP

After a detailed comparison of the mobile robot navigation method, robot performance and the whole solution through various inspections, a SEER Robotics integraend-to-end industrial logistics solutionstor finally won the bid for the internal logistics automation transformation project of the factory floor. The successful implementation of this project not only realizes the automation and intelligence of the workshop logistics, but also greatly reduces the personnel input and saves a lot of labor costs for the enterprise.

MORE

SEER ROBOTICS INJECTS NEW VIGOR TO WEIYI HOLDING IN TRADITIONAL TEXTILE INDUSTRY

After making a general survey on the domestic textile industry, we can find such problems as universally bad working environment and high labor intensity of workers even if the industry has a huge development prospect. As a result, the enterprise is faced with difficult personnel recruitment, high staff mobility, high cost and low efficiency. The textile enterprises are badly in need of intelligent transformation, so as to save the costs and improve the production capacity. However, due to the complex scenario, it is difficult for a company with smart logistics to solve the transformation problem for them in the original plant environment.

MORE

SEER ROBOTICS EMPOWERS LUYUAN ELECTRIC VEHICLES TO BUILD THE COUNTRY'S LARGEST ELECTRIC VEHICLE ASSEMBLY WORKSHOP

Luyuan Zhejiang's vehicle manufacturing base covers an area of 53,000 square meters. The distribution of parts and components is naturally scattered. It needs intelligent logistics to help this country's largest electric vehicle assembly workshop sprint to the goal of producing 10,000 units per day!

MORE

WHAT HAS SEER ROBOTICS DONE TO RISE HILTI’S INBOUND & OUTBOUND EFFICIENCY BY 200%?

The customer coming on the scene is Hilti (Shanghai), a branch company specializes in the manufacture of light power tools, as well as the production of wired and rechargeable electric hammer drills, wired and rechargeable screwdrivers, rechargeable electric saws and grinders, etc. Enriched lines of products make the company face complicated and diverse transportation problems of raw materials and finished products. Inefficient and complicated transportation is in urgent need of a transformation into smart logistics.

MORE

SEER ROBOTICS HELPS QIANJIANG ROBOT MOVE THE INTELLIGENT FACTORY INTO AN EXHIBITION HALL!

Zhejiang Qianjiang Robot Co., Ltd is a subsidiary owned by Zhejiang AISHIDA Electric Co., Ltd, and is a high-tech robot enterprise with independent intellectual property rights and core technologies.

MORE

WHAT TO DO ABOUT SMART LOGISTICS IN THE CONSUMABLES INDUSTRY, SEER ROBOTICS GIVES THE ANSWER!

The case customers in this issue are the head enterprises in the large consumables industry, the products sell well in many countries and regions such as mainland China, Southeast Asia, Europe and the United States, and the production line in short supply is challenging the efficiency of traditional manual transportation, and it is a major demand for traditional enterprises to intelligent and digital transformation.

MORE

SEER ROBOTICS DELIVERS AN ONE-STOP SOLUTION FOR AS/RS IN ELECTRONIC INDUSTRY

The customer coming on the scene is a core supplier in the field of private-network wireless communication in China. With the state-level Enterprise Technology Center and Industrial Design Center, our customer is well-known as a National High-tech Enterprise, a National Technological Innovation Demonstration Enterprise, and a large-scale comprehensive electronic backbone enterprise having a history of 80+ years.

MORE

SEER ROBOTICS LOGISTICS SOLUTION FOR PNEUMATIC COMPONENT PROCESSING WORKSHOP

With the comprehensive advancement of a new round of technological revolution, in the global manufacturing system, production automation and the realization of intelligent internal logistics have become one of the most concerned topics for many manufacturers. At the same time, it is also an important issue that needs to be resolved in each plant workshop. Especially for some powerful large-scale enterprise workshops, as production automation matures gradually, the solution of internal logistics automation and intelligent will become the next threshold for building smart factories, which is of great significance for achieving efficient and lean production.

MORE

SEER ROBOTICS LOGISTICS SOLUTION FOR AUTOMOTIVE ELECTRONICS PROCESSING WORKSHOP

At present, my country is in an important stage of transforming from a manufacturing power to a manufacturing power. In the production workshops of most small and medium-sized enterprises, the level of production automation in some links has gradually matured, but in terms of workshop logistics and transportation, it is still mainly solved by manpower. With the continuous increase of labor costs and the serious shortage of young and middle-aged labor in the manufacturing industry, the use of robots to replace people to solve logistics and transportation has become an important way for enterprises to improve their production efficiency.

MORE

SEER ROBOTICS LOGISTICS SOLUTION FOR AUTOMOTIVE PARTS PROCESSING WORKSHOP

In the global manufacturing system, the automobile industry has experienced more than 100 years of development, and the level of production automation has gradually matured. However, in the production and processing workshop, the level of internal logistics automation is still relatively low, which is not conducive to adapting to the current production needs of flexible manufacturing and intelligent manufacturing. With the technological innovation of mobile robots, the emergence of laser natural contour navigation mobile robots has brought new solutions to the realization of intelligent logistics in automobile processing and auto parts production workshops, and has played a significant role in realizing flexible manufacturing and improving production capacity.

MORE

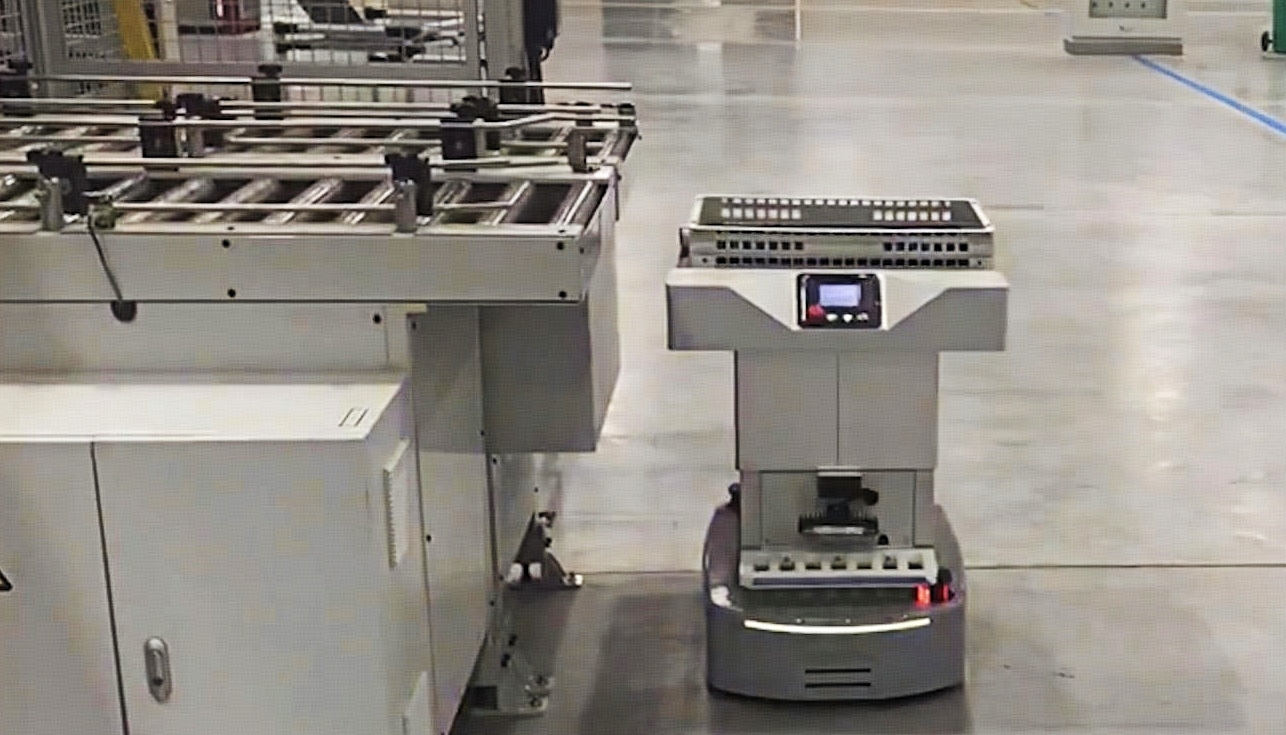

CROSS-FLOOR HIGH-EFFICIENCY CONVEYANCE, SEER ROBITICS HELPS TAILIN MEDICAL ENGINEERING TO CONTINUE TO IMPROVE EFFICIENCY

Recently, mobile robot controller leader SEER Robitics standard products, officially landed in the factory of Zhejiang Tailin Medical Engineering with cross-floor high-efficiency conveying of factory materials.

MORE

SEER ROBOTICS JOINS FORCES WITH MACHINE MANUFACTURING LEADER KMJP TO LAUNCH A NEW CHAPTER IN THE JAPANESE MARKET

The leader of mobile robot controllers SEER Robotics and the well-known Japanese conveying equipment manufacturer KMJP, have further consolidated their partnership, and the KMJP exhibition hall has fully landed SEER Robotics mobile robot standard products.

MORE

SEER ROBOTICS ENTERS STRATEGIC PARTNERSHIP WITH POLISH HEAD INTEGRATOR PROMAG

SEER Robotics, the leader in mobile robot controllers, has announced a strategic partnership with PROMAG, Poland's leading provider of intelligent warehousing and logistics solutions, to jointly promote the innovation of intelligent warehousing and logistics in Poland and bring more new options for the digital transformation of end customers in Poland and Europe.

MORE

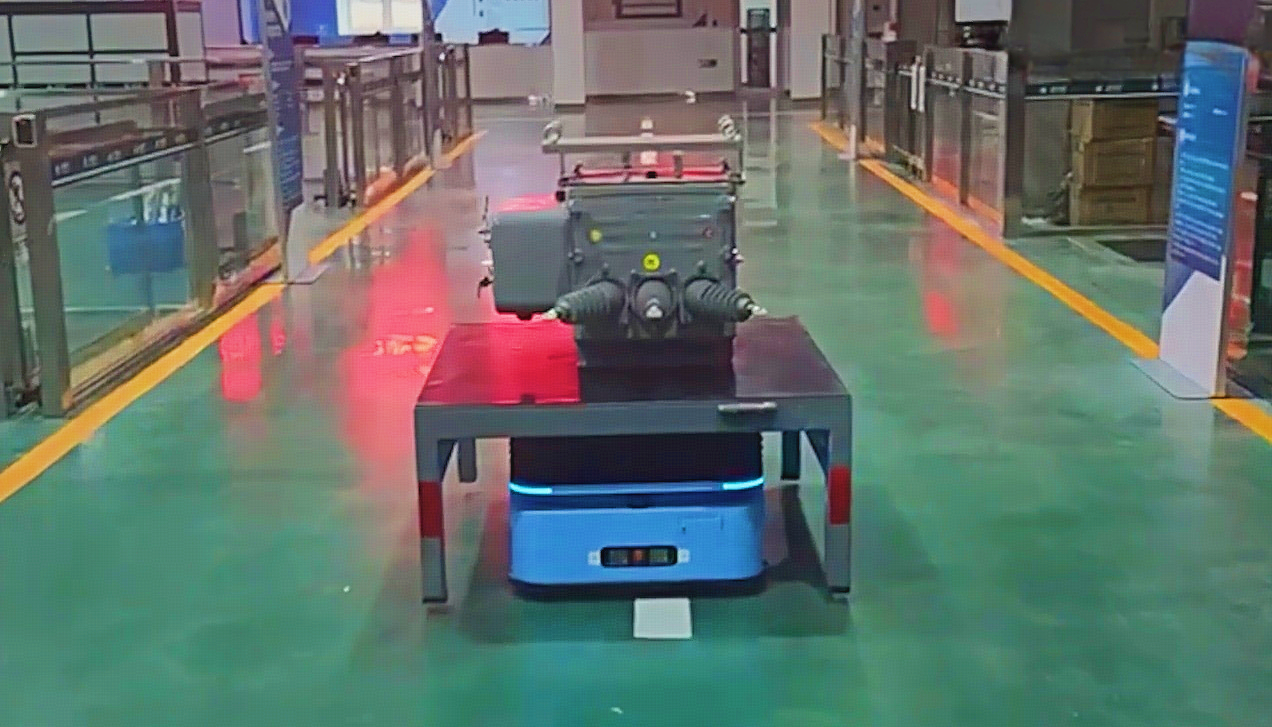

IN-DEPTH ELECTRICAL MANUFACTURING INDUSTRY, SEER ROBOTICS HELPS TO BUILDING OF INTELLIGENT LOGISTICS FOR THE STATE GRID

Recently, SEER Robotics successfully landed the mobile robot latent jacking project in State Grid Material Center. By improving the efficiency and safety of material operation and realizing operation automation and intelligence, it helps the State Grid Material Center to improve energy efficiency and really achieve cost reduction and increase efficiency.

MORE

THE KING OF AMR CONTROLLER COST PERFORMANCE FROM SEER ROBOTICS

The automation company hoped to achieve intelligent transfer of engine materials in the automation equipment production shop through the introduction of AMR solutions, replacing the original manual work, thereby improving the efficiency and flexibility of the workshop operation.

MORE

SEER ROBOTICS HELPS 3PL INDUSTRY UPGRADE WAREHOUSE AUTOMATION

The rapid upsurge of global trade has led to the growth of demand in the consumer market, and the soaring volume of orders has accelerated the pace of development of the third-party logistics (3PL) industry, while at the same time it has also put forward higher requirements for 3PL companies, how to control the cost of warehousing, but also be able to efficiently meet the needs of customers. The key issue of cost reduction and increasing efficiency is in front of all 3PL enterprises.

MORE